Our range of Pneumatic Control Components includes a variety of valves and manifolds, which have been engineered to provide maximum durability and ease of use. We offer a range of sizes and configurations to suit your specific control needs, so you can be sure you’re getting the right solution for your application.

What happens when a solenoid valve goes bad?

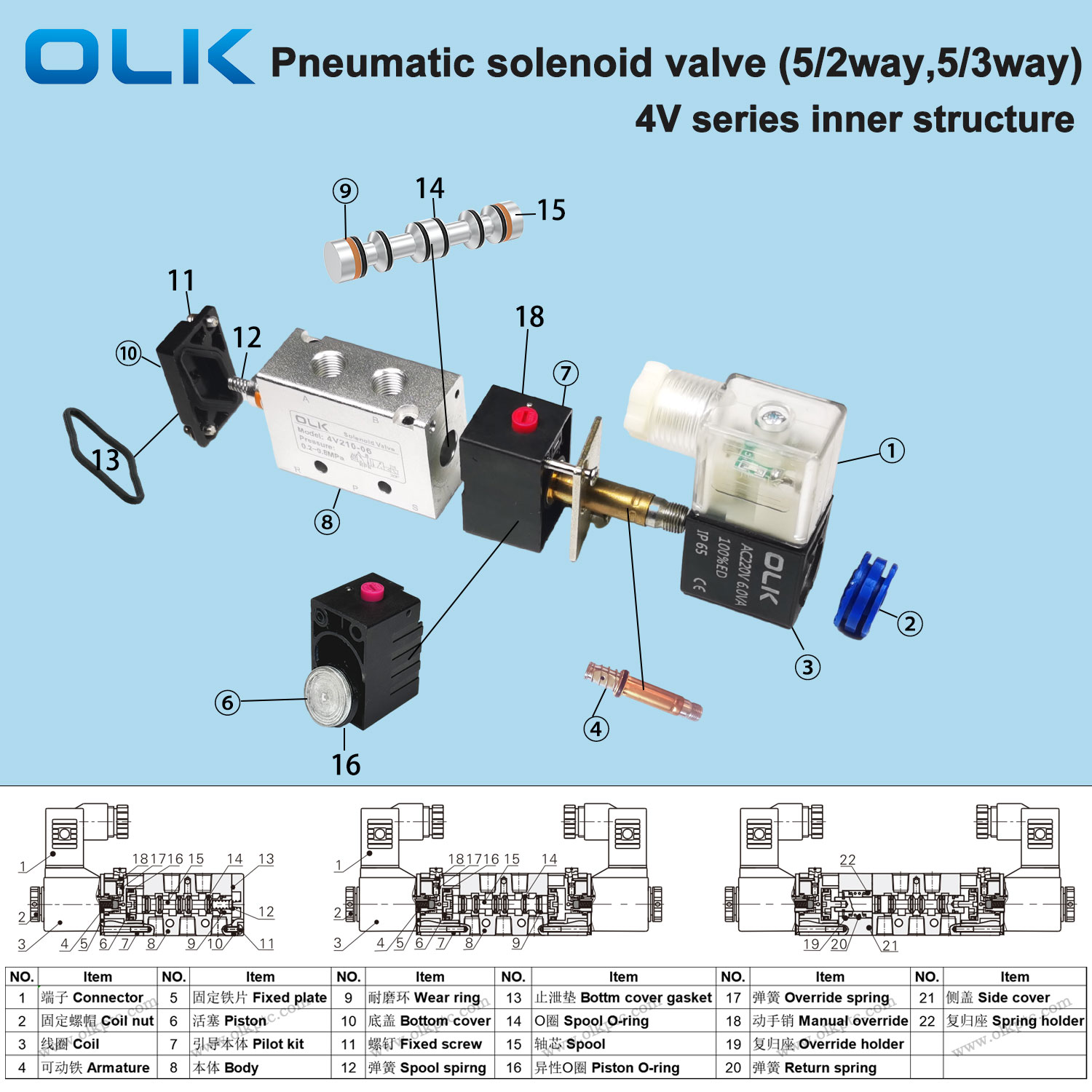

a. The grease between the valve body and the valve core has dried up, the friction is large, and the valve core cannot move. In this case, it is recommended to disassemble the product and add grease.

b. The life of a pneumatic solenoid valve is usually measured in times. Depending on the use environment, it can reach millions to tens of millions of times. However, it can only be used for a few weeks on some high-frequency automated production lines and is considered a consumable.

After the life test on the solenoid valve test bench, it is found that the parts that have reached the end of their life are often the seals on the valve core. Other parts are intact. It is very troublesome to replace the seal ring by yourself, and it may cause functional damage to the seal, which requires customized tools to assist.

What is the main cause of solenoid failure?

a. The lubricating grease between the valve body and the valve core has dried up, causing high friction and preventing the valve core from moving. In this situation, it is recommended to disassemble the product and add lubricating grease;

b. The product has air leakage and the pressure inside the valve body is low;

c. Coil quality issue, unable to open the commutation channel after power on.

How do air control valves work?

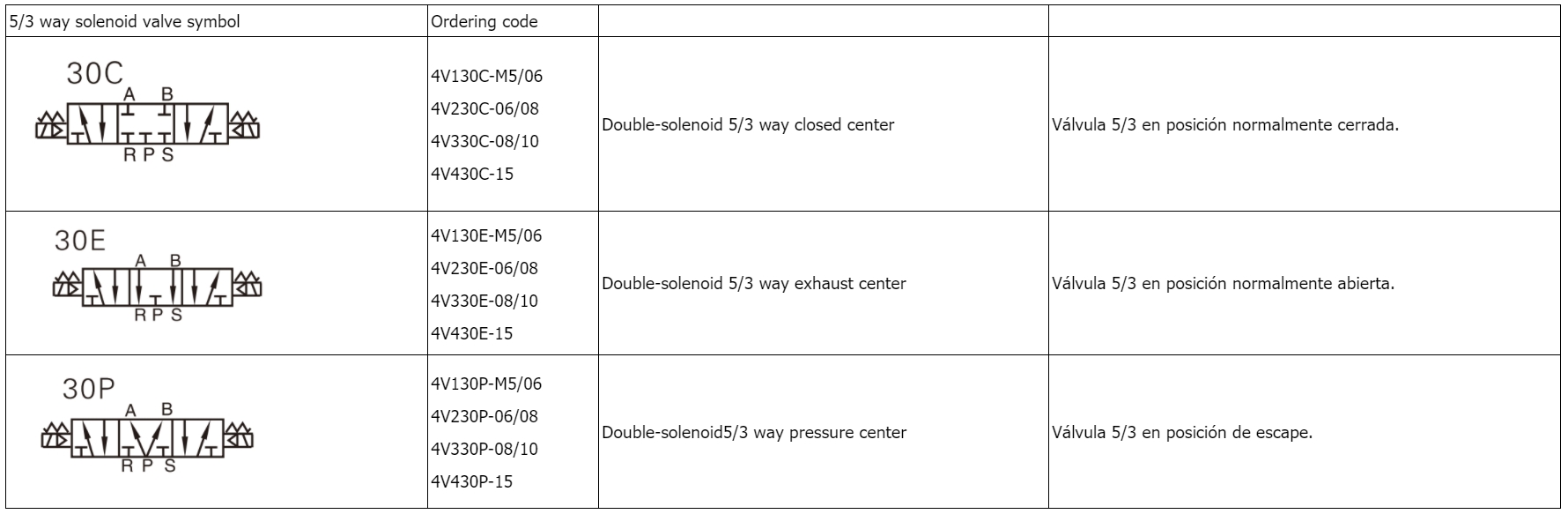

Pneumatic control reversing valves offer three air path options: two-way three-port, two-way five-port, and three-way five-port. The valve core switches by pneumatic pressure to change the direction of airflow. This pneumatic pressure is known as pilot pressure or control pressure, provided externally.

What is a pneumatic manual control valve?

The 3R hand lever valve controls the direction by direct manual operation. The two-way three-way valve has one inlet, one outlet, and one exhaust port. The inlet is equipped with a filter screen to remove impurities from the air, preventing contamination and air leakage of the sealing ring.

Hand lever valve adopts hand lever drive, facilitating manual control of gas flow direction for users, with simple operation and no need for external power source.

What is the function of foot valve in pneumatic system?

Foot pedal valves are direct-acting valves controlled by foot pedals, avoiding the need for cumbersome manual operation and adjustments, thus offering convenience and speed. The product is available with optional self-locking function to prevent accidental operation and ensure safety.

What is the function of a one-way valve?

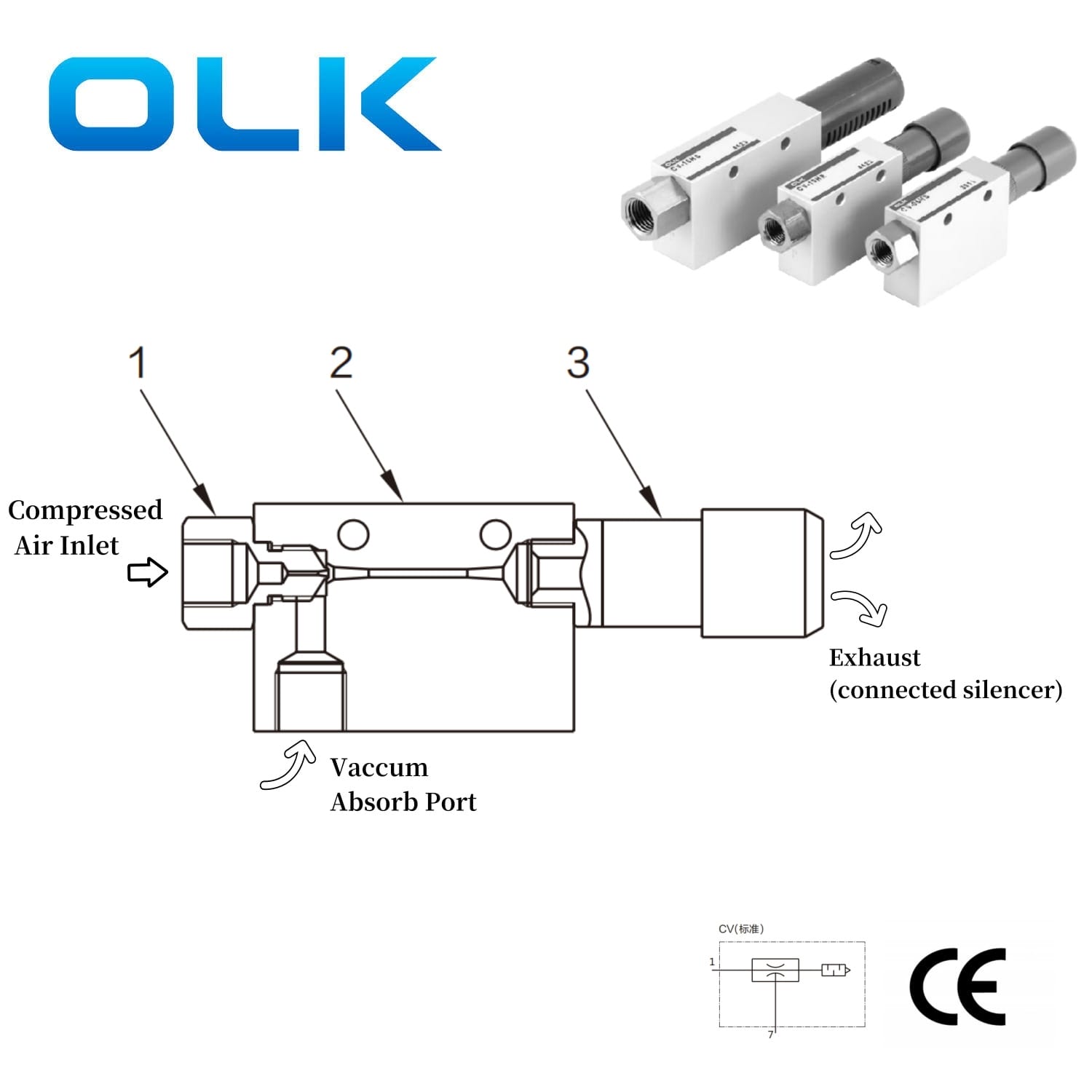

unidirectional throttle valve is a valve that controls fluid flow by changing the throttle section size. It features a unidirectional structure and throttle structure.They offer reliable flow with good stability and precision.